Sheroz Earthworks Can Be Fun For Everyone

Table of ContentsRumored Buzz on Sheroz EarthworksA Biased View of Sheroz EarthworksSheroz Earthworks Can Be Fun For AnyoneExcitement About Sheroz EarthworksThe Single Strategy To Use For Sheroz Earthworks

For any kind of earthwork service provider, it is essential to carry out collaborate with top quality, accuracy, and on schedule. Utilizing maker control in work devices makes it possible for optimizing the various phases in the earthwork process, from intending to the maintenance phase - topcon laser levels. The machine control system helps the maker operator in achieving the target airplane quickly and conveniently

The maker control system guides the operator with centimeter precision. With Xsite PRO 3D, you'll always understand exactly just how much to reduce or load. Your regional Xsite technical assistance can assist you and assist with any problems without visiting the site. Remote support saves money and time, as it decreases downtime in jobsites.

The smart Trick of Sheroz Earthworks That Nobody is Discussing

Our system's components are very carefully made to endure the harsh problems of construction sites. Comparison of the very same project performed making use of machine control versus the standard technique exposes that, on average, the traditional method requires 50% even more time to complete the same job as the technology-assisted method.

Sounds great? Enter the Xsite device control system; it's right here to provide you with a substantial advantage when working with earthmoving equipment. Discover just how Xsite Maker Control can improve your efficiency and ensure work safety and security! We comprehend that finding out a brand-new innovation might seem like a drag, however do not stress! Our friendly and professional neighborhood assistance solutions have obtained you covered, ensuring that you can keep functioning smarter without disruptions while on duty! With remote assistance, your regional Xsite supplier can supply assistance or troubleshooting without having to visit the site! What kind of excavators does device control fit? Xsite Device Control systems can be set up to any excavator from mini excavators to big mining excavators.

How does maker control job? In 2D systems, the machine is outfitted with adjusted inclination sensors.

The system is really easy to find out the basics can be taught in under one hour of training. With Xsite you don't need to bother with finding out all the tips and technique at when. Added training and directions are constantly offered over remote assistance when needed. Get in touch with your local Xsite supplier to learn more! How does the remote assistance job? A wireless internet link makes it feasible to develop a remote link between the equipment control system and the solution.

The 6-Second Trick For Sheroz Earthworks

What kind of information layouts Xsite systems support? Xsite Device Control systems sustain open typical documents formats, allowing seamless info circulation from one system to another. Supported data formats: 2D-Maps: DXF Factor files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Designs: DXF, XML What elements are mounted on my equipment? Depending on your option of system (with or without placing, i.e - topcon gps., 2D or 3D), your machine is equipped with inclination sensing units, a controller device, and a display/operating panel.

Many equipment and software program remedies exist to assist identify a machine's existing position on the earth and compare it with a wanted layout surfaceand building and construction drivers can do more to take advantage of the benefits. Equipment control is using different positioning sensing units and a screen to give the operator with a reference in between the position of the pail or blade and the target grade.

Relying on the configuration, machine control systems can supply the operator with a basic visual overview to bucket or blade placement, or can automatically relocate the blade to grade by speaking with the equipment's hydraulics - https://www.wattpad.com/user/sherozau. There are maker control systems readily available for simply about any type of machine: graders, dozers, excavators, soil and asphalt compactors, scrapers, leaners, milling devices, and pavers

Some Ideas on Sheroz Earthworks You Need To Know

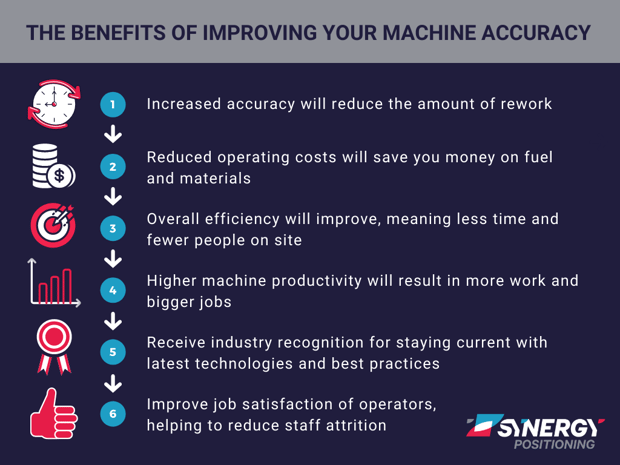

Some advantages consist of minimized rework, boosted task effectiveness, and lower evaluating prices. Machine control can also assist enhance productivity and decrease overall prices. This modern technology is altering the means the building industry functions. Building tools without equipment control will end up being a distant memory and the advantages obtained from it will be many.

Trimble machine control systems provide a myriad of advantages to anyone that utilizes earthwork equipment and, at EarthCalc, we click here for more info can offer you with 3D declare your machine control-enable devices. Not exactly sure if device control deserves the expense? Consider the adhering to reasons why you require to consider this option.

Utilizing GPS straightened with your 3D style documents, these systems virtually ensure that you will certainly get rid of or put the appropriate quantity of material at the building and construction site. On many construction websites, remodel is a common and irritating fact, but with Trimble equipment control, you can get rid of the need for rework.

The Sheroz Earthworks Diaries

Often, with Trimble equipment control, you can get rid of excess devices at a details job site. A job that may have needed the use of 3 or 4 items of digging deep into equipment now may need only two pieces of devices to complete the same task in less time. This allows you to move your equipment to one more work website and handle multiple jobs at one time.